Overview

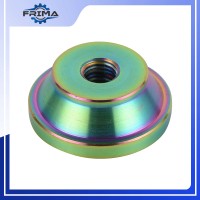

Custom Made Rod End Bearing

Custom Made Rod End Bearing is a component or assembly that has been manufactured by machining, a process that removes material from the workpiece using cutting tools. Machined parts are used in a variety of industries, including the automotive, aerospace, and construction industries.

Custom Made Rod End Bearing can be made from a variety of materials, including metals, plastics, and composites. The type of material used will depend on the application of the part.

What specification of Custom Made Rod End Bearing FRIMA can offer?

1. Size

- Threaded Holes

- UNC & UNF threads from #2 up to 0.5 in.

- Metric threads M1.2 and above.

2. Radii

Turned outside corners will typically include a 0.005 in. chamfer.

Minimum hole size:

- Minimum on-axis and axial: 0.04 in. (1mm)

- Minimum radial: 0.08 in. (0.5mm), 0.04 in (0.5mm) for aluminum and brass

3. Grooves:

- Minimum OD groove width: 0.047 in. (1.2mm)

- Minimum OD groove width for aluminum and brass:0.019 in (0.5mm)

- Maximum OD groove depth: 0.95 in. (24.1mm)—varies with a groove width

4. Custom Made Rod End Bearing Tolerance Standards

| CNC Machining Standards (DIN ISO 2768-1(1991-06) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tolerance class | tolerance(mm) | |||||||||||||

| Metal (ISO 2768-F) | Plastic (ISO 2768-F) | |||||||||||||

| 0.5 to 3 | Over 3 to 6 | Over 6 to 30 | Over 30 to 120 | Over 120 to 400 | Over 400 to 1000 | Over 1000 to 2000 | 0.5 to 3 | Over 3 to 6 | Over 6 to 30 | Over 30 to 120 | Over 120 to 400 | Over 400 to 1000 | Over 1000 to 2000 | |

| F | ±0.05 | ±0.05 | ±0.1 | ±0.15 | ±0.2 | ±0.3 | ±0.5 | ±0.05 | ±0.05 | ±0.1 | ±0.15 | ±0.2 | ±0.3 | ±0.5 |

Show All

5. General Tolerances For Shape And Position

| General tolerances for shape and position (DIN ISO 2768-2(1991-04) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tolerance class | tolerance(mm) | |||||||||||||

| Straightness and Flatness | Verticality | Symmetry | ||||||||||||

| 10 | 10 to 30 | 30 to 100 | 100 to 300 | 300 to 1000 | 1000 to 3000 | to 100 | 100 to 300 | 300 to 1000 | 1000 to 3000 | to 100 | 100 to 300 | 300 to 1000 | 1000 to 3000 | |

| H | ±0.02 | ±0.05 | ±0.1 | ±0.2 | ±0.3 | ±0.4 | ±0.2 | ±0.3 | ±0.4 | ±0.5 | ±0.5 | |||

Show All

Materials Used for Custom Made Rod End Bearing

CNC Precision Machining Automotive Ball Joints can be applied to various materials, including metal, plastic, and wood. Different lathes are needed for turning metal and wood. According to the types of machined part materials, certain maintenance and safety precautions may be required for the lathe.

Here are some common materials for automotive precision parts below. If the material you required is not listed in the table, please contact us.

Surface Finish at FRIMA – Process for Custom Made Rod End Bearing

Here is a wide selection of metal surface finishing services of your choice for the machined precision machining custom Made Rod End Bearing to improve the part appearance, surface smoothness, corrosion resistance, and other characteristics.

| As machined | Description |

|---|---|

| As machined | Standard finish with a surface roughness of 1.6 μm (126 μin). |

| Smoothing | The standard smoothing surface roughness (Ra) is 0.8 μm (63 μin). |

| Painting | They were spraying paint, pigment, or color to a solid surface as a colored protective layer. |

| Passivation | Remove ferrous contaminants or use a light coat of protective material to create a shell. |

| Powder Coating | A functional and decorative finish is applied as a free-flowing, dry powder. |

| Anodizing | Type II (anodizing color or clear) or Type III (anodizing hard coat) |

| Polishing | Produce a smooth and shiny surface. |

| Black Oxide | Formed a black conversion coating on metal parts. |

| Bead Blasting | Removing surface deposits by applying fine glass beads at high pressure. |

| Abrasive Blasting/Sandblasting | Smoothing and cleaning a hard surface by forcing solid particles across that surface. |

| Electroplating/Plating | Form a thin coherent metal coating on an electrode. |

| Brushing | Polishing the metal with grit results in a unidirectional satin finish. |

| Chromate Conversion coating | Increase the corrosion resistance while maintaining conductive properties |

Show All

Frequently Asked Questions

The following parts are a good fit for CNC turning:

Rotary parts with high precision requirements.

Rotary parts with complex surface shapes.

Rotary parts with lateral machining.

Ultra-precision and ultra-low surface roughness parts.

Parts with special threads.

The main costs related to CNC machining can be divided into machining time, start-up cost, material cost, and feature cost. To reduce costs, you need to understand the impact of these factors on costs.

– The best way to reduce machining time is to design features that can be processed quickly, such as by selecting the correct inner corner radius, reducing the cavity depth, increasing the wall thickness, limiting the thread length, and designing holes of standard size.

– The material cost can be reduced by considering the size of the required blank and the cost and machinability of bulk materials (softer alloys process faster).

– Start-up costs can be reduced by reducing the number of part rotations or repositioning required to complete the part, such as dividing the geometry into multiple parts that can be assembled later.

– Using tolerances only when strictly necessary, deleting all text and letters, and avoiding multiple surface treatments can reduce feature costs.

Read more detail in our complete guide on how to reduce the cost of CNC machining parts.

CNC turning is used for creating a variety of parts, including auto parts, knobs, tubes, gears, toy parts, flywheels, crankshafts, hubs & disc cams. It is most often used to manufacture CNC parts online for automotive, aerospace, medical, and other industries.

CNC turning center, the equipment or machines for CNC turning service, is a computer-controlled 3, 4, or 5-axis machine that has capabilities of turning, drilling, tapping, and milling, using live tools with powered rotary tool turret, dual spindles, Y-axis, and multiple turrets. While the CNC lathe machine is a simpler 2-axis with one spindle, basically composed of headstock, carriage, tailstock, and bed.

– CNC turning centers have more complex structures than CNC lathes.

– CNC turning centers have higher production capabilities and versatility than CNC lathes.

– CNC lathes are generally flat-bed type while turning centers are usually slant-bed type.

– There are only minimal protective enclosures around the lathe while the turning center is commonly equipped with full enclosures to keep chips and coolant splashes within the machine.

Heat treatments can be applied on precision CNC turned parts to improve their key properties such as hardness. Heat treatment can be applied to metal parts throughout the manufacturing process.

– Hardening: used to harden the material and make it stronger, also decreases the ductility.

– Annealing: heats metal parts to a very high temperature and then slowly cools to achieve the desired microstructure.

– Normalizing: used to relieve internal stresses that were created during machining service.

– Quenching: heating the metal to a very high temperature, followed by a rapid cooling step.

There are many types of CNC turning operations for CNC lathe services that can be performed on a live tooling lathe in CNC turning factory, including Hard turning, Parting, Facing, Boring, Reaming, Taper turning, Drilling, Knurling, Threading, Grooving, etc., comes in varying tools, cost and set-up time.

– Tapered turning: produce a cylindrical part of which diameter decrease from one end to another.

– Hard turning: suited for materials with a Rockwell C hardness greater than 45, typically performed after heat treated.

– Spherical generation: create a spherical finished surface, turning around a fixed rotary axis.

– Facing: a turning operation in which the workpiece is machined to its center.

– Parting: create deep grooves that remove a completed or part-complete component from its parent stock.

– Grooving: similar to parting, but only cut to a specific depth from outside or inside of the workpiece.

– Drilling: remove materials to drill holes from the inside of a workpiece with drill bits held stationary in the tailstock or tool turret of the lathe. Boring: enlarge or smooth an existing hole.

– Knurling: cut a serrated pattern onto the surface of the workpiece with a knurling tool, to change or enhance the visual effect or hand grip.

– Reaming: remove a small volume of materials from a drilled hole, for highly accurate diameters.

– Threading: turn standard and non-standard screw threads, which generally means single-point threading.

– Polygonal turning: non-circular forms machining operation without interrupting the rotation of the raw material.

Would you like to learn more about Custom Made Rod End Bearing ?

Request an Instant Quote for Your Projects!

You will get a professional one-stop solution to boost your business.

We’re glad to answer any questions you may have!

What our clients say

“ We are deeply grateful to the FRIMA Machining team for their outstanding R&D services and skillful craftsmanship. FRIMA has played a pivotal role in our project's success, and we are currently carrying out positive testing in Saudi Arabia. ”

Bill, Research & Development Manager