Overview

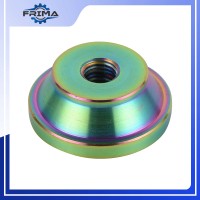

Custom Metal Stamping Parts

FRIMA is a professional custom metal stamping parts manufacturer. During the metal stamping process, blanks or coils of sheet metal feed through one or more die and toolsets. These die and tool set form and cut the sheet metal into its desired shape.

At FRIMA, we perform a variety of custom metal stamping operations, including:

- Blanking

- Bending

- Punching

- Coining

- Drawing

- Embossing

- Piercing

- Curling

FRIMA Special stamping features

Our custom metal stamping methods are fast, reliable, and multi-functional. We deliver parts that provide exceptional performance to our customers. In addition, we have the ability to add special features to our stamped parts such as:

- Threaded

- Countersunk

- Numbered

- Embossed elements such as logos

- Assembled

- Staking

- Joining

All our dies and tools are engineered and built in-house, using our state-of-the-art EDM and CNC machines. Creating our own die and toolsets allows us to maintain tight tolerances of up to 0.005″ throughout the entire metal stamping process.

Custom Metal Stamping Capabilities

As a professional manufacturer of metal stamping, our customers rely on our expert design and development services. We create a range of metal components in all sizes, from simple to intricate.

We provide service and support to our customers throughout the entire process, from prototype development through high-volume production. We have the capability to process orders of up to 50 million parts.

Our custom precision metal stamping produces a variety of components, such as:

- Electronic Terminals

- Sensor components

- Yokes

- Thrust washers

- Heat sinks

- Printer cartridge blades

- Medical Components

- Inserts

- Fuse clips

- Brackets

- Contacts

- Covers

- Latches

- Furniture parts

Production Methods

At FRIMA, we utilize several metalworking processes to create custom metal parts.

Progressive Die Stamping

In progressive die stamping, the sheet metal acquires its shape by passing through a series of workstations. Each die is capable of cutting, bending, punching, coining, embossing, drawing, or shaving the metal. Depending on the complexity of each part, the metal can pass through as few as one or as many as 40 steps. Progressive die stamping typically results in more waste than multi-slide or four-slide stamping, however, progressive die stamping tools are usually faster to set up.

Industries Served

FRIMA had been serving into below Industries:

- Aerospace

- Appliances

- Automotive

- Electrical Distribution

- Communications

- Construction

- Renewable Energy

- General Manufacturing

- Medical/Medical Devices

- Military/Defense

- General Manufacturing

Given our capabilities, we can serve the custom metal stamping needs of a broad range of industries and can projects of all sizes.

Full-Service Custom Metal Stamping Parts

Our services go beyond custom metal stamping. We offer secondary services to provide end-to-end solutions to our customers, including:

- Plating

- E-Coating

- Heat-treating

- Stress relieving

- Pick and Place

- Screw Insertion

- Reel-to-reel

- Tape and reel

Quality control and quality enhancement are at the heart of what we do. To learn how we can create custom metal stamping parts to your specifications, please contact us.

Frequently Asked Questions

Would you like to learn more about Custom Metal Stamping Parts ?

Request an Instant Quote for Your Projects!

You will get a professional one-stop solution to boost your business.

We’re glad to answer any questions you may have!

What our clients say

“ We are deeply grateful to the FRIMA Machining team for their outstanding R&D services and skillful craftsmanship. FRIMA has played a pivotal role in our project's success, and we are currently carrying out positive testing in Saudi Arabia. ”

Bill, Research & Development Manager